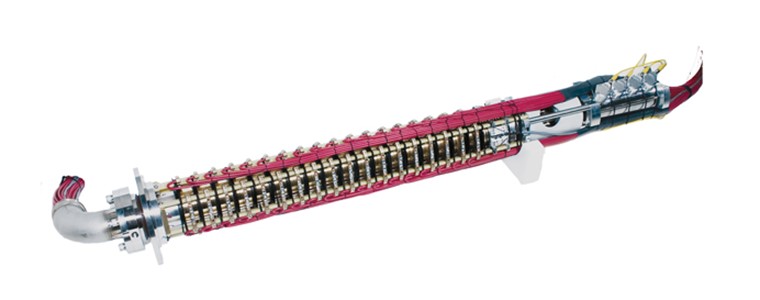

Electrical Slip Ring Model 176 with FORJ

Request a quote for: Electrical Slip Ring Model 176 with FORJ

Get your non-binding quote today and see how we can help.

The Model 176 is comprised of electrical power and signal passes, and provides superior performance and reliability in demanding operational environments. The Model 176 may be used for high voltage and high current applications, customized to meet customer specific needs. The slip ring is waterproof rated to IP66, with the option for greater ingress protection.

The Model 176 may be constructed for subsea use where underwater operation is required. The slip ring may be fluid-filled, and pressure compensated. Additional options are available for high voltage use in submerged applications. For the hazardous locations, the Model 176-X variant is fully certified, as a flameproof and explosion proof enclosure.

The electrical slip ring (ESR) is comprised of electrical power and signal passes. Highly configurable, it is customized to meet customer specific needs, providing superior performance and reliability in demanding operating environments. For hazardous area environments, there is an option for a fully certified, flameproof enclosure.

The fiber optic rotary joint (FORJ) can be configured with many of Moog Focal’s single-channel or multi-channel, singlemode or multimode fiber joints. Our FORJs are capable of working with all fiber types, sizes and wavelengths, and meet insertion loss performance typical of customer requirements.

Features

- Electrical passes rated up to 7200 V / 20 A

- Pigtail exits are capable of being sealed

- Sealed housing design tested to IP66 standards

- Can accommodate a variety of wire and cable types

- Maintained type certification for Hazardous locations

- Stainless steel construction

- Rugged design intended for harsh environments

- Reliable operation under shock and vibration

- Underwater designs available

- Combined with Fluid Rotary Unions (FRU), see Model 173

Benefits

- Compliance with the highest quality standards for design, manufacture and test

- Maintenance free operation

- More than 30 years of proven field performance

- Integration with fiber optic rotary joints (FORJ) and fluid rotary unions (FRU) to provide a complete rotating interface solution

Applications

- Seismic survey winches

- Remotely Operated Vehicles (ROVs)

- Winch and TMS applications

- Mine countermeasures

- Towed instrument arrays

- Oceanographic winches (surface and subsea)