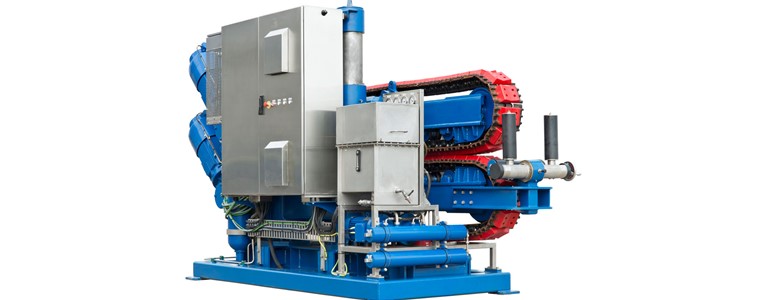

CEMAC Offshore Track Tensioners

Request a quote for: CEMAC Offshore Track Tensioners

Get your non-binding quote today and see how we can help.

Safe and accurate cable and pipe handling

The unique electrically driven technology enables the CEMAC offshore track tensioners to safely and accurately control the installation and recovery of offshore power cables, telecom cables, fibre optics and pipes. The in-house developed control paired with a robust design ensures a seamless operation at low energy consumption.

Precision solutions for every application

The electro-hydraulic CEMAC offshore track tensioners can be delivered in standardised configurations or fully tailored to match your requirements. They can be designed in 2-, 3-, and 4-track configurations with both vertical and horisontal cable inputs. The compact and modular system unlocks great potential in pulling force, even with limited deck space available.Regardless of project requirements, the CEMAC track tensioners can be designed to improve safe cable handling, while constantly monitoring the product integrity, which is available through built-in SCADA functions.

Seamless integration

MacArtney Offshore Wind Solutions excels in designing and manufacturing offshore cable and pipe handling systems for the energy industry. Leveraging our expertise in automation and control, we seamlessly synchronise our CEMAC electro-hydraulic track tensioners with a suite of complementary equipment and activities, including cable carousels, and loading arm- and quadrant operations. With endless integration possibilities within a centralised control system and efficient operation alongside third-party equipment, MacArtney enables comprehensive deck layouts for your vessel and integration into existing setups.

Minimise downtime

The CEMAC track tensioners are available with a remote diagnostics tool enabling MacArtney technicians to remotely monitor and supervise in real-time. By eliminating unnecessary offshore engineering support, this unique feature generates substantial cost-savings in minimised downtime to the respective project.

Features and benefits

- Proven track record

- Minimal pressurised oil

- Electrically driven, eliminating the necessity for external HPUsSmall footprint

- Optimised energy consumption

- Accurate controllability

- Integrated control system

- Designed for seamless system integration

- Advanced product integrity monitoring system

- Comprehensive data logging

- Low noise operation

- DNV/BV compliant design

Options

- Full customisation

- Bundled lay

- Top-loaded versions

- Wide opening versions

- Active front end for energy recovery

- Service and maintenance program

- Tailored spare parts philosophy

- Wireless remote control

- Data output for vessel control integration

- Remote diagnostics

- Tarpaulin cover

- CE marking

- Certification according to DNVGL-ST-0378 (2.22), DNVGL-E2.7-3, and ILO 152